Call: 08045814162

Aluminium Fabrication

Product Details:

X

Aluminium Fabrication Price And Quantity

- 1 Piece

Aluminium Fabrication Trade Information

- Cash in Advance (CID)

- 7 Days

- All India

Product Description

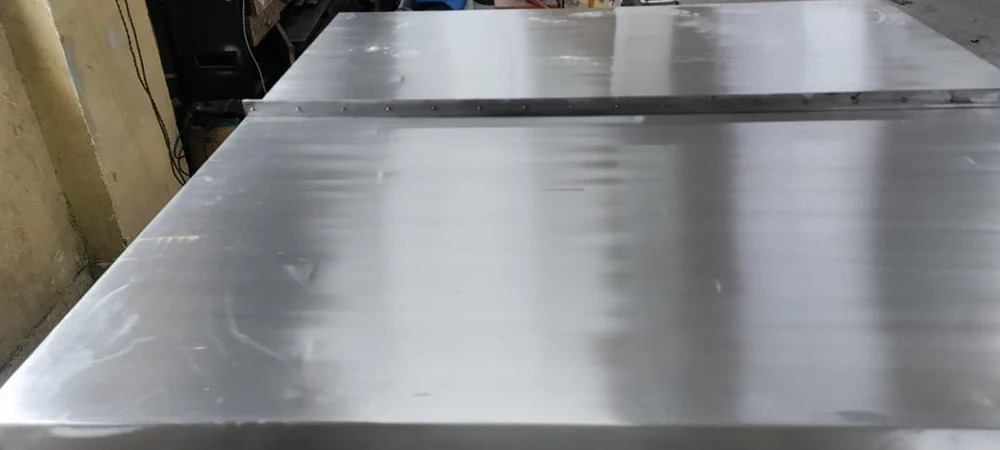

Unlock a world of eminent stability with our top-ranking Aluminium Fabrication services, designed for high precision and glorious durability. Whether you seek sheet, frame, or panel fabrication, our offerings guarantee a smooth, corrosion-resistant finish. Serving as a manufacturer, supplier, and service provider in India, we deliver customized solutions spanning simple to complex requirements for the automobile, aerospace, and EV industry. Grab this long-lasting deal, benefiting from advanced CNC machines and superior welding, ensuring every project meets distinguished industry standards.

Aluminium Fabrication: Commercial Versatility & Features

Our aluminium fabrication is renowned for its glorious versatility in commercial applications such as automobiles, aerospace, and electric vehicles. Utilizing top-ranking CNC machines, laser cutters, and press brakes, we craft precise frames, panels, and structures. The eminent corrosion resistance, high precision tolerance, and smooth finishes make it ideal for intricate usage and robust applications. Whether for customized or simple designs, our fabrication guarantees durability and seamless integration into advanced engineering projects.

Supply Ability & Trade Terms: Seamless Goods Transport

Experience flawless supply ability with prompt drop-off and efficient goods transport for your aluminium fabrication orders. We ensure meticulous handling and timely delivery through major FOB ports, minimizing your expenditure on logistics. Adaptable payment terms provide commercial convenience and flexibility, supporting effortless procurement for manufacturers and service providers alike. Rely on our distribution network to deliver premium-quality material and meet demanding production schedules across Indias industrial landscape.

Aluminium Fabrication: Commercial Versatility & Features

Our aluminium fabrication is renowned for its glorious versatility in commercial applications such as automobiles, aerospace, and electric vehicles. Utilizing top-ranking CNC machines, laser cutters, and press brakes, we craft precise frames, panels, and structures. The eminent corrosion resistance, high precision tolerance, and smooth finishes make it ideal for intricate usage and robust applications. Whether for customized or simple designs, our fabrication guarantees durability and seamless integration into advanced engineering projects.

Supply Ability & Trade Terms: Seamless Goods Transport

Experience flawless supply ability with prompt drop-off and efficient goods transport for your aluminium fabrication orders. We ensure meticulous handling and timely delivery through major FOB ports, minimizing your expenditure on logistics. Adaptable payment terms provide commercial convenience and flexibility, supporting effortless procurement for manufacturers and service providers alike. Rely on our distribution network to deliver premium-quality material and meet demanding production schedules across Indias industrial landscape.

| Fabrication | Simple Fabrication, Customized Fabrication. |

| Industry | Automobile, Aerospace & EV industry |

| Machineary | CNC machines, laser cutters, press brakes |

| surface finishes | Powder Coating, Polishing or Other Finishes |

| Welding Quality | TIG, MIG, or other welding techniques. |

FAQs of Aluminium Fabrication:

Q: How is aluminium fabrication customized for different industry needs?

A: We offer both simple and customized aluminium fabrication, tailored for a range of industries including automobile, aerospace, and electric vehicles. Each project is engineered to client specifications using advanced machinery and varied finishes.Q: What surface finish options are provided for aluminium fabrication?

A: Clients can choose from powder coating, polishing, or specialized finishes to suit their operational and aesthetic requirements. Each finish enhances the corrosion resistance and surface smoothness of the final component.Q: Where do you provide drop-off and goods transport services?

A: We supply and drop-off goods across India, coordinating with leading FOB ports. Our goods transport ensures safe and timely delivery to your site, supporting smooth integration into your production schedule.Q: What welding techniques are utilized in your fabrication process?

A: Our fabrication employs TIG, MIG, and other suitable welding techniques, each selected according to structural requirements and material thickness to guarantee optimal strength and longevity.Q: When should one consider aluminium fabrication for structural parts?

A: Aluminium fabrication is ideal when you require long-lasting, corrosion-resistant solutions with precise tolerances for parts like frames, panels, and structures. Applications in high-performance or demanding environments benefit greatly from its robust nature.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese