Call: 08045814162

Machine Reconditioning Work

Product Details:

X

Machine Reconditioning Work Price And Quantity

- 1 Unit

Machine Reconditioning Work Trade Information

- Cash in Advance (CID)

- 7 Days

- All India

Product Description

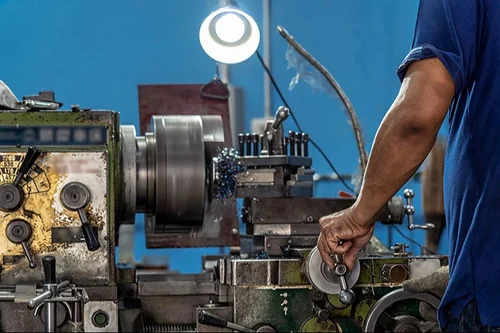

Reconditioning of World-Class Machine Tools:- Grinders: Cylindrical, Surface, Angular, Tool & Cutter

- Special Grinders: Flute, Thread, Worm

- Copying lathes & Center lathes

- Milling machines, including Die Sinking

- Gear cutting machines: Hobbing, Shaping

- Press machines: Hydraulic, Pneumatic, Mechanical

- Various CNC, GPMs, and SPMs

- CNC Angle Heads and Live tools

- Transfer lines

- Plant Equipment: Compressors, Generators, Cranes

- Retrofitting and Upgradation of machines

- Manufacturing of Machine Spares (HMT spares Ex-stock)

Comprehensive Machine Reconditioning Services

We provide end-to-end machine reconditioning work encompassing all stages, from careful disassembly to final testing. Each project is managed by seasoned professionals, ensuring that machines meet stringent operational standards and industry requirements. Our facility is equipped to handle machines weighing up to 20 tons, making us the ideal partner for large-scale industrial equipment refurbishment in India.

Industries We Serve

Our expertise extends across various sectors including automobile, textile, engineering, and manufacturing. We understand the nuanced demands of each industry and tailor our services accordingly. Whether for production lines or specialized machinery, our proven methods help restore performance and longevity, reducing costly downtime and maximizing productivity.

FAQs of Machine Reconditioning Work:

Q: How is the machine reconditioning process carried out for metal, cast iron, or steel machines?

A: The machine reconditioning process involves disassembly of the equipment, thorough inspection to identify wear or damage, precision machining of critical components, careful assembly, and rigorous testing to ensure restored functionality. This approach is suitable for machines constructed from metal, cast iron, or steel.Q: What types of machines and industries can benefit from your reconditioning work?

A: We recondition machines weighing up to 20 tons for the automobile, textile, engineering, and manufacturing industries. Our services help clients prolong the lifespan of their equipment, improve efficiency, and reduce operational costs.Q: When should a company consider machine reconditioning instead of replacement?

A: Machine reconditioning is recommended when performance declines, frequent breakdowns occur, or when routine maintenance no longer delivers desired results. Reconditioning is a cost-effective alternative to replacement, especially for large machines where procurement and installation are time-consuming.Q: Where is your service available and how can customers book a reconditioning job?

A: Our services are available across India. Customers can contact us directly to discuss project requirements and arrange for site assessment. We offer convenient online and offline payment modes for seamless transactions.Q: What is involved in the inspection and testing phases during reconditioning?

A: Inspection covers a detailed assessment of all machine components to identify faults or excessive wear. Testing ensures that the reassembled machine meets safety, performance, and durability standards before delivery, guaranteeing reliable operation.Q: How does after-sales service benefit clients post-reconditioning?

A: Our after-sales support includes ongoing maintenance, troubleshooting assistance, and additional refurbishment if required. Clients benefit from minimized downtime and continuous machine performance, ensuring peace of mind after every serviced project.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese